Sharing stories of impact and discovery across the St. Jude research enterprise.

Progress: A Digital Magazine

Seeing is believing: Bringing virtual reality into the clinic

See how St. Jude investigators are using virtual reality in their work.

- Histology detectives magnify the clinical and research mission of St. Jude

- Drug which blocks stress granule formation offers insight into biomolecular condensates

- A light in the dark: Illuminating the biology of catastrophic pediatric diseases with fluorescence microscopy

- St. Jude Global poster showcase provides insights and updates on Global Initiative for Childhood Cancer

Editor's selections

-

Clinical Collaborating for Care: Developing a New Global Standard for Sickle Cell Disease Treatment

-

Research Addressing treatment-related mortality: Student’s research spotlights need for supportive care

-

Outreach Bridging the pediatric cancer budgeting gap in national cancer control plans

-

Clinical St. Jude advice to young adults with sickle cell disease: Stay connected

-

Research Global palliative care requires on-the-ground understanding

Featured series

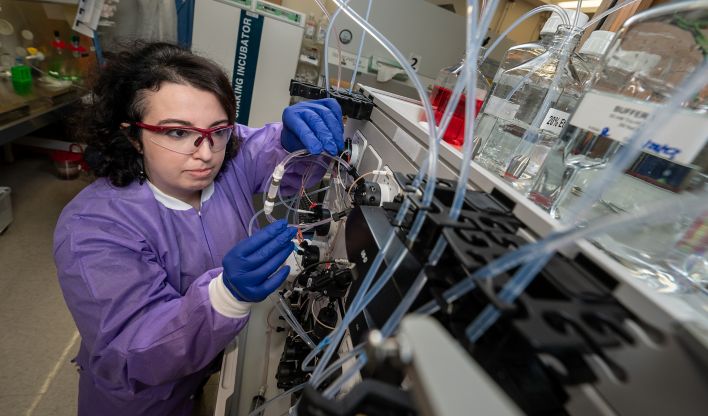

The St. Jude Vector Laboratory advances gene therapy through viral vectors, advancing scientific and therapeutic innovation.

Meet the investigators in the Biostatistics Shared Resource to learn how this under-recognized field is a critical component of successful research.

Learn more about how the St. Jude Good Manufacturing Practice facility is manufacturing lifesaving therapeutics for children with cancer and catastrophic diseases

Research from the Center for Applied Genome Engineering plays a pivotal role in discovery.

About us

Scientific advances make the mission of St. Jude Children’s Research Hospital possible every day. St. Jude Progress tells the stories of those advances from the investigators, laboratory researchers and clinical scientists who are making them.